Improving purchase order management at origin might be a dry subject for some, but not for us. Why? Because the best supply chain in the world cannot consistently deliver-on-time if suppliers do not manufacture on time. In other words, it is much harder to win if you start from behind.

Background

We have managed two projects that shifted order management from a home country office to China. One was for a USA multi-national corporation in 2012 and another for an Australian retailer in 2017.

Both times, before implementation, there was concern that supply performance would decrease without the direct involvement of the home office team at every step.

However, both projects were successfully implemented with no disruption to supply and, rather, immediate and lasting improvement in supplier delivery performance was achieved.

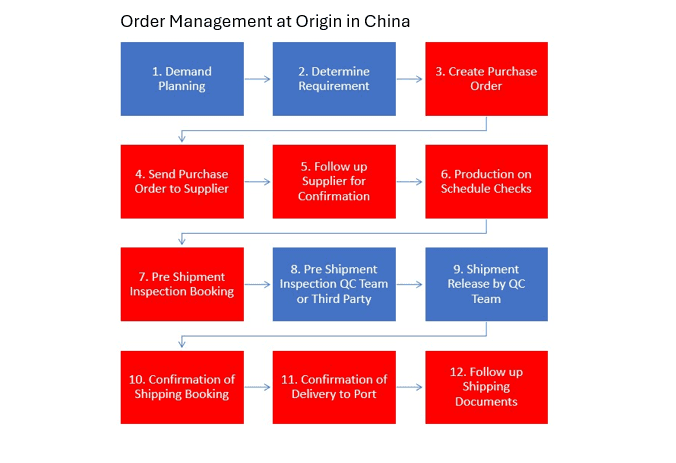

The attached table shows the order management process which was basically the same for both companies. Steps marked in red are the ones that were moved to the China order management team.

Why does order management at origin get results?

- Communication! Communication! Communication! In both projects, China based, Chinese team were able to communicate more effectively with Chinese factories than the home office team. Improved communication led to better results.

- Diligence. These two teams followed-up to the brink of obsession. Any outstanding issue was chased down and resolved as a matter of urgency. At the risk of generalizing, we believe this is a Chinese characteristic and one of the reasons most things move with breathtaking speed in China.

- Removal of Time Zone Delay: This is particularly relevant for the USA. Removal of delays in response caused by difference in time zone enabled issues to be resolved days (sometimes, weeks) earlier.

- Improved Productivity. Wages in China are increasing but are still lower than many western countries. For a lower cost, China order management teams can be established with more people who (because of location) are more effective.

Key Success Factors

- Team selection: As with everywhere else in the world, it is important to ensure that the team has the right aptitude and attitude. In both projects, the team was led by an awesome team leader who led by example and ensured high performance.

- Clarity. Make sure the process (who does what when how) is crystal clear. Ensure team are accountable to meet deadlines and achieve KPI's.

- Discipline. Expect a high standard of discipline from the order management team and ensure they expect the same from suppliers.

- Systems. Ensure the home office team and the China team are able to share information easily. Because of internet restrictions in China, this could mean changing how documents are managed in the home office. For example, for the Australian retailer all documents were moved to SharePoint because this platform could be accessed without issue by the China team.

- Platform for (Legally) Employing Team in China. To establish a team in China you need a Chinese business platform for employment and management of team in compliance with Chinese law.

Conclusion

The best supply chain in the world cannot consistently deliver-on-time if suppliers do not manufacture on time. Order management at origin is an effective way to achieve immediate and lasting China supply improvement. Is supplier late delivery pulling down your supply performance? If yes, it may be worth considering setting up an order management team at origin.