Planes, Trains and Automobiles - Tips for Successful China Sourcing Trips!

China sourcing trips can deliver significant ROI if executed well. Here are some trip planning tips.

Read MoreExpert insights, industry trends, and practical advice for successful sourcing and supply chain management in China.

China sourcing trips can deliver significant ROI if executed well. Here are some trip planning tips.

Read More

Over the years, we’ve observed what it takes to succeed in China sourcing. While many factors contribute, these five are absolutely foundational and can’t afford to be missed.

Read More

Social audits often highlight excessive working hours. This isn't new, but the causes are complex.

Read More

Genghis Khan didn't conquer half the world by accident. Before his armies crossed into new territory, he sent forward scouts months ahead—not just to assess threats, but to secure supply lines, establish cache points, and build relationships with local traders.

Read More

Strong supplier partnerships are built on mutual respect, clear expectations, and market-competitive pricing.

Read More

A fractional supply chain manager based in China offers flexibility, expertise, and boots-on-the-ground responsiveness without the overhead of a full-time hire.

Read More

The current sourcing environment presents an excellent opportunity to launch tenders on existing China-sourced products to ensure that your existing pricing is market competitive.

Read More

Use buyer trips for strategic signoffs and connection-building. Don't waste them on initial verification. Have your local team prepare everything in advance, so buyers can maximise their time and impact.

Read More

Managing your China supply chain with local team members is a strategic enabler of supply-led competitor advantage. Their presence enhances responsiveness, builds stronger supplier relationships, and ensures smoother operations across the board. In a world where supply chain resilience is more important than ever, investing in local expertise is a smart move for any business sourcing from China.

Read More

Don’t default to the obvious solution. Challenge assumptions. Dig deeper into alternatives. Match the solution to your actual requirements—not just what everyone else is doing.

Read More

Private label drives profit and differentiation—so why do new product development projects keep getting delayed? A common culprit is bottlenecks in the retailer home office.

Read More

The humble Yangmei shows the power of understanding China supply clusters.

Read More

Sometimes it's good to look in the mirror and sanity check your own processes.

Read More

Is your organization taking a strategic approach to overseas sourcing, or are you leaving money on the table through fragmented buying?

Read More

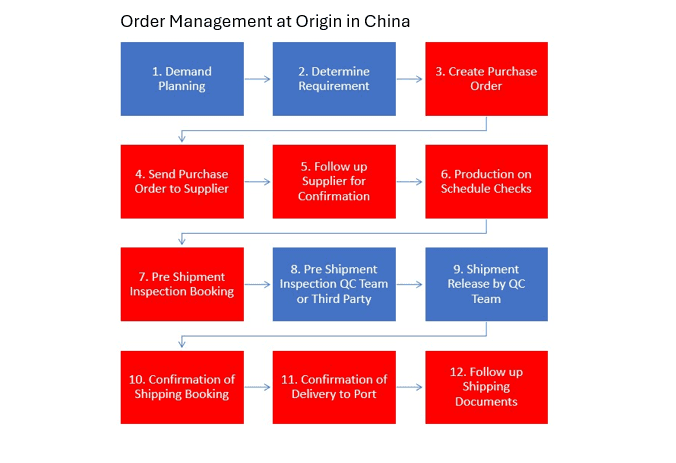

This an article that we published on LinkedIn in June 2018. Since then, we have seen more fantastic results of Order Management at Origin and the principles outlined in this article remain the same. Is supplier late delivery pulling down your supply performance? If yes, it may be worth considering setting up an order management team at origin.

Read More

Bottom line: This isn’t just ethical—it’s essential risk management and a business growth enabler.

Read More

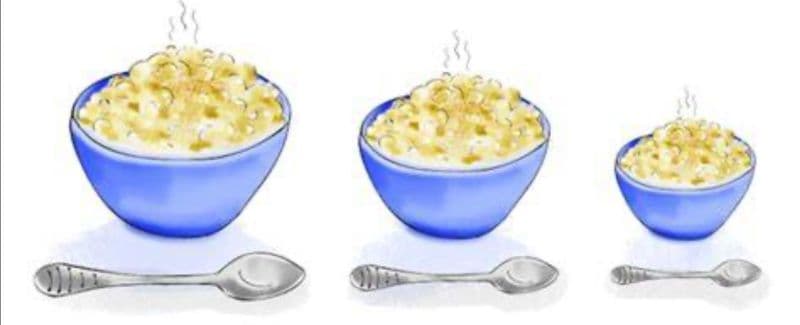

When you’re visiting a factory it’s ok to be impressed with size, but at the same time, make sure you are evaluating suitability and select the one that is 𝕛𝕦𝕤𝕥 𝕣𝕚𝕘𝕙𝕥 for you.

Read More

They are not all blue, but blue is overwhelmingly the dominant colour. Why is this so?

Read More

The best supply improvement strategies fail without buy-in. When launching a new sourcing office, communicate plans in advance and get key stakeholder buy-in before launch.

Read More

To have an effective China+1 strategy your alternative supply must be: → Same or lower cost than China. → Not geographically or economically tethered to China. If not, you are adding cost and complexity for no real benefit.

Read More

We are a Shanghai company, but our operational offices are in Ningbo. Here is why.

Read More

The new differentiator isn’t IF you source from China—it’s HOW you source from China.

Read More

Pre-shipment inspections are a valuable control that protects your supply chain from disruption, your customers from defective products and your company from financial loss. Pre-shipment inspections have been around for decades but are still not used by many brands and retailers. Here is the case for conducting pre-shipment inspections before shipment release.

Read More

Beware the lone wolf of international sourcing - able to fly into China, visit factories, detect issues and single-handedly resolve them before flying back triumphant to the home office.

Read More

How to close the gap between delivery on time requirement and delivery on time reality? Consider using the Supply Superpower: Managing Orders at Origin.

Read More

How to decide whether to work with a trading company or buy direct from factories when sourcing from China.

Are you an international brand or retailer that has identified the need for team members on the ground in China but is NOT prepared to establish an entity there? You can take advantage of an outsourced sourcing and supply management service in China rather than establishing your own entity.

Read More

Imagine if you could cut warehousing and distribution costs by over 30% while simultaneously reducing bottlenecks at distribution centres. This is achievable when shipping store-ready pallets directly to stores from China bonded logistics parks.

Read More

How mid-market companies can use strategic relationship building to achieve supply outcomes that rival the largest buyers.

Read More

China's supply chain landscape is undergoing a profound transformation that extends far beyond simple economic indicators. While the country maintains its position as a global manufacturing powerhouse, behind this figure, China's supply chain is undergoing a profound transformation. This is not just a change in the growth rate, but a complete restructuring of the entire supply chain ecosystem. Understanding these shifts is crucial for businesses navigating the evolving global trade environment.

Read More

Implementing effective quality control measures is crucial for successful China sourcing. Learn the essential best practices that will protect your business and ensure consistent product quality.

Read More

Starting your China sourcing journey can be overwhelming. This comprehensive guide covers everything you need to know as a beginner, from finding suppliers to managing quality control and logistics.

Read More